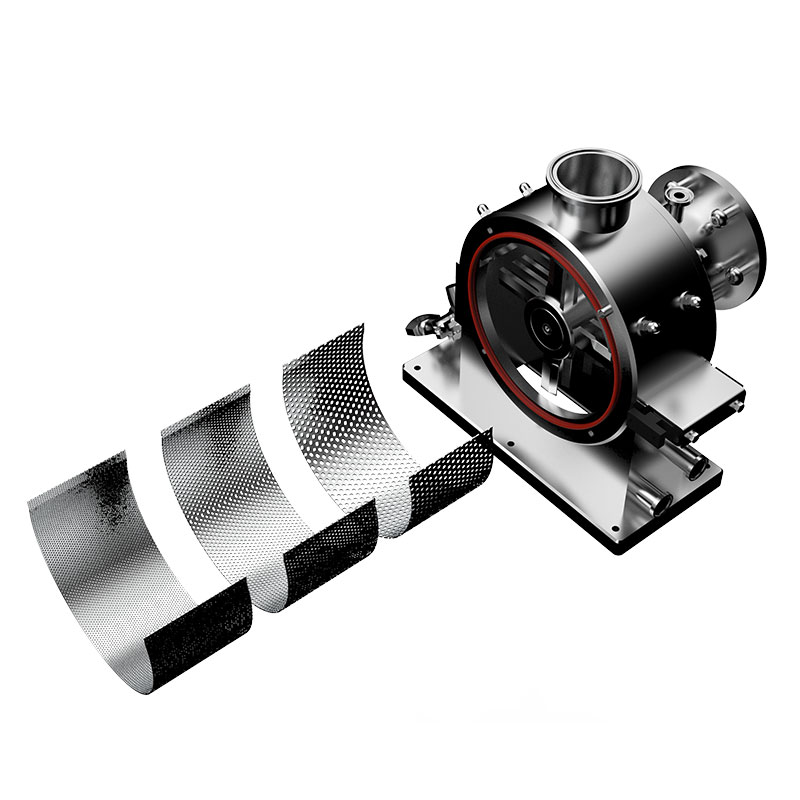

The operating principle is based on widely tested milling methods: inside the milling chamber, already equipped in the standard version with a cooling jacket and temperature probe for constant monitoring of the process conditions, a rotor equipped with double profile blades collides repeatedly the substance fed until it is reduced to the size imposed by the calibration screen.

TECHNICAL DATA AND PRODUCTIVITY INDICES

THE TECHNICAL DATA AND THE PRODUCTIVITY INDICES LISTED ARE PURELY INDICATIVE AND MAY VARY, EVEN SUBSTANTIALLY, ACCORDING TO THE PRODUCT TREATED AND THE PROCESS REQUIREMENTS. FOR THE AFOREMENTIONED REASONS IT IS ALWAYS ADVISABLE TO CONTACT THE COMPANY FOR MORE DETAILED INFORMATION BY SUBMITTING YOUR PROJECTS / NEEDS TO OUR TECHNICIANS SO THAT WE CAN ADVISE AND SERVE YOU IN THE BEST POSSIBLE WAY.

| SCHEDA COMPARATIVA | Modello: TB 80 | Modello: TB 150 | Modello: TB 300 |

|---|---|---|---|

| Capacità: | Fino a 100 Kg/h | Fino a 1000 Kg/h | Fino a 2000 Kg/h |

| Finezza raggiungibile: | <100 µm * | <100 µm * | <100 µm * |

| Peso (indicativo): | 290 Kg | 180 Kg | 560 Kg |

| Motorizzazione: | 4 kW, trifase, gestita a mezzo inverter | 1.1 kW, trifase, gestita a mezzo inverter | 11 kW, trifase, gestita a mezzo inverter |

| N giri del motore: | 400-7000 RPM | 400-5000 RPM | 400-3500 RPM |

| Materiali di costruzione: | Parti a contatto AISI 316L (1.4404) , altre parti AISI 304 (1.4301), tenute meccaniche radiali sulla parti rotanti in GYLON, FDA app. | Parti a contatto AISI 316L (1.4404) , altre parti AISI 304 (1.4301), tenute meccaniche radiali sulla parti rotanti in GYLON, FDA app. | Parti a contatto AISI 316L (1.4404) , altre parti AISI 304 (1.4301), tenute meccaniche radiali sulla parti rotanti in GYLON, FDA app. |