The issue of containment is of ever-increasing importance in the chemical-pharmaceutical field, especially in relation to the increased toxicity of the products treated, such as API (Active Pharmaceutical Ingredient) and especially HAPI (Highly Active Pharmaceutical Ingredient). When handling active ingredients, it is necessary to classify these substances according to the OEL (Occupational Exposure Level, operator exposure limit) or OEB (Occupational Exposure Band, operator exposure range) index, according to the in order to identify the most suitable management system.

The OEL index defines the average concentration (g / m3) of a substance measured for 8 hours in the air breathed by an operator in the workplace. Therefore, the term "containment" refers to the input process of a biological agent (active medicinal products, pathogens) or of another substance within a defined room.

The OEB index (1, 2, 3, 4, 5) is assigned on the basis of the toxicity of a given substance in its pure state in order to carry out a risk assessment and select the most suitable procedures and systems for a given product.

cGMP's (Current GOOD MANUFACTURING PRACTICE'S)

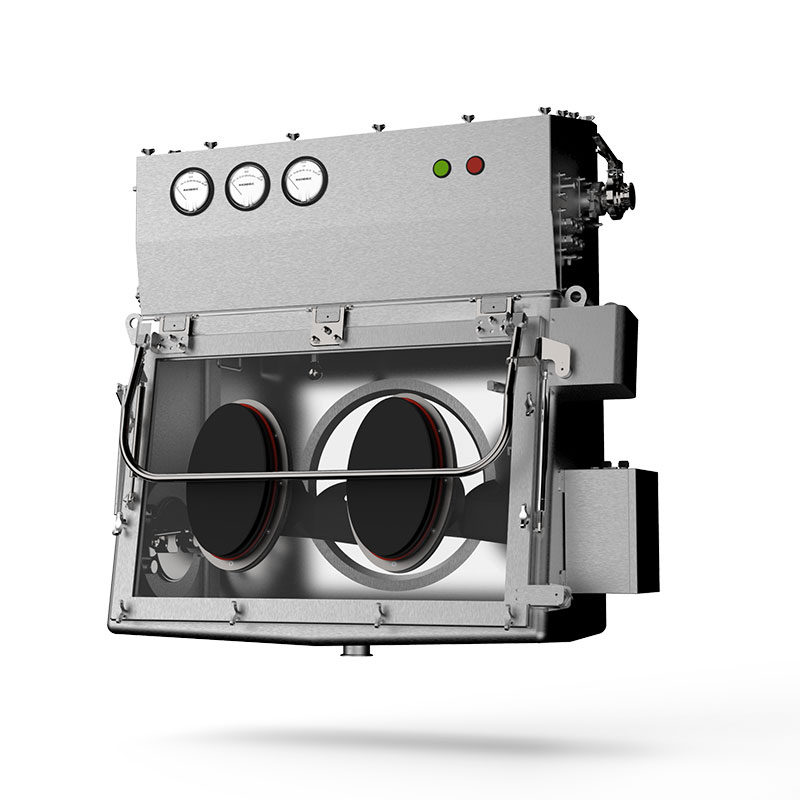

ISO 14644-7 Separative devices (clean air hoods, glove boxes, isolators, and mini-environments)

ISO 10648-1 Containment enclosure

– Part 1 Design principles ISO 10648-2 Containment enclosure

– Part 2 Classification according to leak tightness and associated checking method AGS-G001-2007 (American Glovebox Society)

Leak test (leak test, according to ISO 10648-2)

Helium test

SMEPAC TEST (Standardized Measurement of Equipment Particulate Containment)

Particle counter at rest for internal environmental class verification according to ISO 14644-1

Integrity test of installed filters according to ISO 14644-3

Glove breach test (According ISO 14644-7),